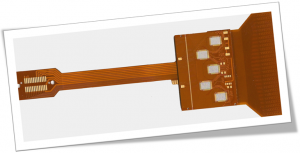

Single-Sided Flex Circuits

Single-sided flex circuits are the most common design. They are composed of a single conductive layer on a flexible dielectric. Although they are usually coated with a protective layer, they can be used without any coating. Flexible printed circuit board components are placed on only one side of single-sided flex circuits.

Single-sided flex circuits are the most popular when it comes to flexible circuits. This is mainly because a single-sider configuration is a most effective and least expensive variant for dynamic flex applications.

Usually, they are manufactured using etched metal or printed conductive inks to produce the intended circuit patterns on the surface of a flexible board. When considering etched metal design, the metal may be made accessible for one or both sides of the unit.

With two side access, a method of laser removal is usually employed to strip the polymer base film off of the board. A specialized variant of the single-sided flexible circuits depends on selective etching to make a circuit pattern with a copper of varying thickness levels in particular areas of the board.

For instance, regions, where flexibility is a priority, may be filled with a thinner copper circuit pattern, whereas, areas requiring greater interconnection may use a thicker pattern.

Back-Bared Flex Circuits

Back-bared flex circuits also have only a single conductive layer, but the conductor is accessible from both sides of the dielectric film. This type of flex circuit is more difficult to produce, but we do offer this design option.

Back-bared flex circuits come second in terms of the most common type of flexible circuits. They are mainly used in applications that require high-density interconnection of circuits.

In contrast to single-sided models, back-bared flex circuits feature two layers of metal that are often connected via a plated-through hole. However, some variants depend on a non-plated-through hole configuration, with both metal layers being accessible and accomplished from the similar side.

A standard double-sided circuit design gives successive layers of cover film, adhesive, and metal on both of the sides of a base film with a plated-through hole ranging from one end to the other.

The top side opening is present on the non-plated-through type for reaching the bottom section.

Double-Sided Flex Circuits

have two conductive layers. We usually design these flexibility circuits with plated through-holes, but this is a design specification that you can change.

We can design flex circuits to mil spec Type V standards if desired. Protective coating can be applied onto one or both sides of this flex circuit.

Multilayer Flex Circuits

Multilayer flex circuits have three or more conductive layers. The layers can be continuously laminated or feature discontinuous lamination for maximum flexibility.

In discontinuous lamination, the areas of the flex circuit that are designed to bend are not bonded.

Rigid-Flex Circuits

Rigid-flex circuits are multilayer structures that combine both rigid and flexible substrates. They are commonly specified in military applications.

Although the design is uncommon, we also offer sculptured flex circuit designs. These flex circuits feature conductive layers of varying thickness throughout different areas of the circuit.

The traces are thin in areas where the circuit is designed to be flexible but thicker in areas where connections are to be made.

For low-power applications with higher voltages where high conductivity is not required, we also offer polymer thick film flex circuit designs. These are usually single-sided flex circuits with traces printed onto a polymer dielectric film.

Similar to a back-bared flex circuit, multilayer flex circuits are used for applications requiring high-density interconnection. Some of their properties also resonate with rigid circuits.

However, multilayer flex circuits usually feature more complex engineering characteristics designed to address particular electrical and electronic connection issues.

Multilayer flex circuits are usually formed from an amalgamation of several single or back-bared flex circuits that are bonded onto a single or double-sided material and laminated with adhesive.

The individual circuits are invented, joined, and plated through, and at that point, plated through and joined again to design a compound assembly with multiple insulating and conductive layers between every interconnected device. It is also possible to construct multilayer flex circuits with the various branching layers out from a central point.

Need more information please contact us