Errors to Avoid When Making A PCB Printed Circuit Board

Today, let us tell you about the five most common errors to avoid when doing PCB Circuit Design.

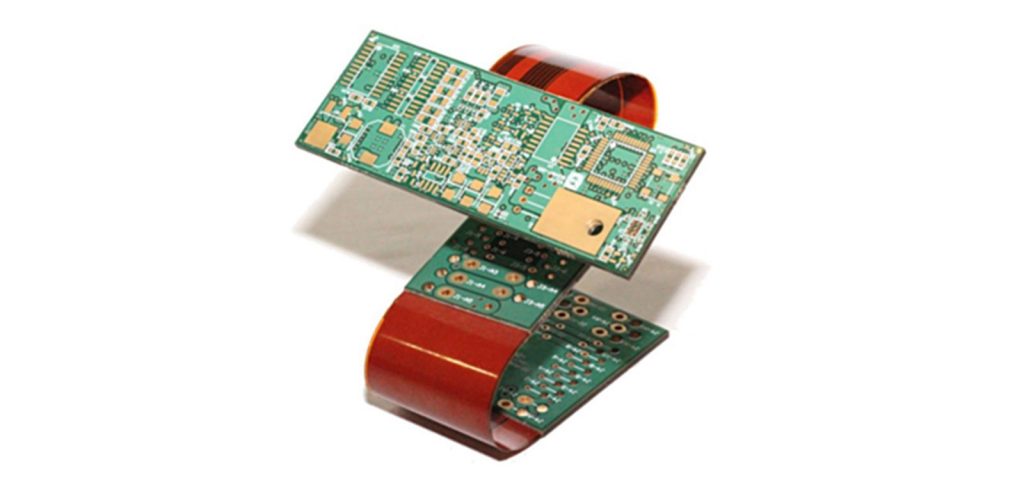

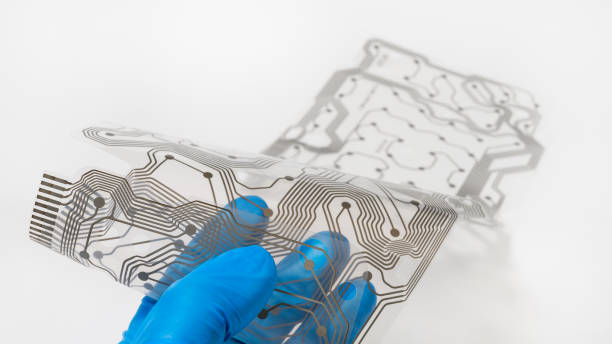

- Make

artisan plates

Nowadays making artisan plates is not what it once was, as it is very time-consuming. It is costly, and with PCB Board Design, connection and material errors generate many errors.

Making PCB Printed Circuit Board manually requires heat transfer paper, toner printer, iron, chemicals or acids to burn the circuit. You also have to spend time looking at the plateau when it is attacked by the acid so that the tracks are well delimited, and the excess copper is removed evenly. However, with all this care, trying to do a good job, there were always pieces or cut left. All this could take hours and would consume much more effort in time. Hence, today it is not a good idea to make artisan PCB in the USA.

(more…)