A PCB or printed circuit board is an electrical circuit that offers mechanical support to the electrical components connected through conductive copper wires. These boards are the primary building block for most electronic projects that help in the creation of compact and less irregular designs.

Over the years, PCBs have evolved into refined boards like flexible printed circuit boards, which are now available in different types. So, to help one understand the flex boards clearly, one can read further and get complete information.

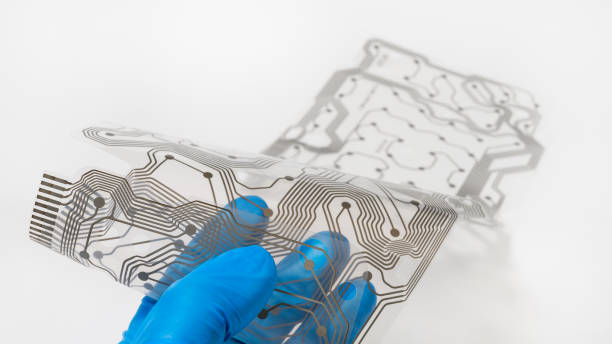

What exactly is the flexible PCB?

Flexible PCBs are the flex circuits that can be molded into any shape. Generally, these types of circuits are utilized for high-temperature and density applications. Moreover, these boards have a conductive layer of copper traces and a polyimide dielectric layer. But, the material selection for the circuit is dependent on various factors like current, temperature, chemical and mechanical resistance, and the type of flex.

The best thing about these circuits is that they are more reliable and come in with few interconnections, and require less space due to their flexibility.

Types of Flexible PCBs available

For those who are curious to know about the types of PCBs available, one can check out the list shared below:

1) Single-layered

It is a circuit that consists of a single conductive layer that rests on the flexible dielectric film. Further, the electric components of the board sit on just one side of the PCB.

2) Double-layered

These PCB circuit boards offer a conductive layer on both sides of the circuit that helps designers connect the electrical components to either side of the conductive layer.

3) Multi-layer

The multi-layer PCBs consist of three or more conductive layers that can easily be separated using a dielectric material. Further, irregular lamination provides high board flexibility.

4) Rigid

Further, these circuits are a combination of flexible and rigid circuits that provide a higher density component than the other circuit boards.

What are the benefits of using flexible PCBs?

After finding out about the flexible PCB and its various types, one must have a complete idea about the benefits of using these circuit boards. So, to help one understand the benefits of this circuit, one can check out the list of points shared below.

1) Fewer errors

The use of the flex circuits shows a significant decrease in assembly errors as most of the designs are accurate, and production is entirely automated.

2) Requires less labor

With flexible PCBs being easy to assemble, one requires less labor, decreasing production errors and costs.

3) Good choice for complex configurations

Because of its flexible and elastic nature, the designers can quickly meet the complex configurations’ needs and easily place them around the folds and edges.

4) Consumes less space

With flexible printed circuit boards being the thinnest circuit boards of around 0.004 inches, there is an automatic reduction in the package size.

And this is a reason why it has become the top choice in comparison to rigid boards.

5) Reduces vibration impacts

The flexible nature of the circuit helps to reduce and absorb the impact of the vibrations, making it the foremost choice among the designers.

6) Minimal use of connectors

With minimal use of the connectors, there is less use for the interconnection points, making it more reliable.

7) Improved airflow

The thinner circuits provide increased heat dissipation, making them suitable for harsh environments. Moreover, the streamlined flow permits the cooling airflow, improving airflow space.

Significance of flexible circuit in the modern world

As flexible boards can be molded in any shape, it is one of the primary reasons it is widely utilized for static application and dynamic flexing. Moreover, these circuits are a perfect match for the applications that need better performance, accuracy, and regular flexing. Some of the applications for which flexible circuit boards are the best include:

- Anti Lock brakes

- Cameras

- Medical devices

- Avionics

- Battery packs

- Fuel pumps

- Barcode equipment

- Airbag systems

- Manufacturing devices

- Satellites and more.

Conclusion

With PCB circuit boards used in several applications, it doesn’t need to work for all applications. Hence, during the preliminary analysis of any design, one needs to examine the benefits and drawbacks of the flexible PCB carefully.