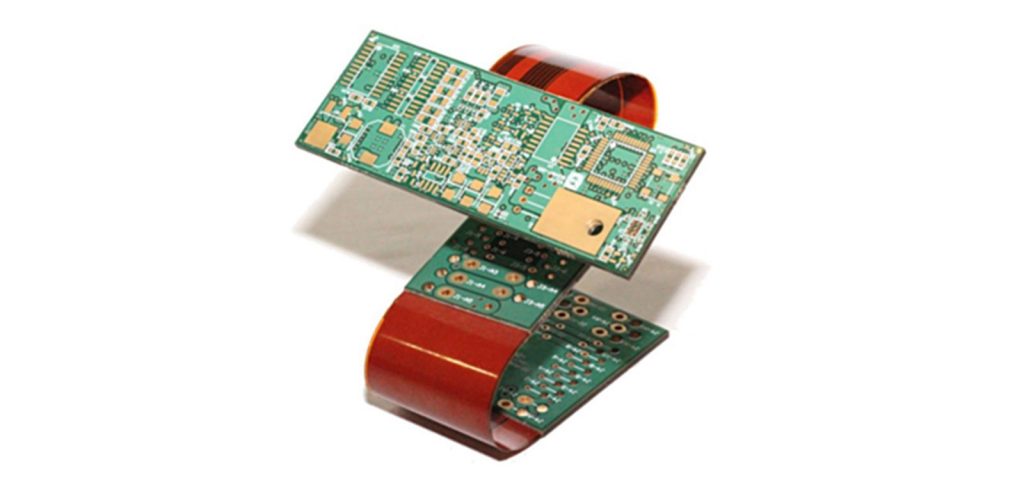

A rigid-flex PCB is a hybrid circuit that incorporates flexible and hardboard circuits components. Even the rigid-flex printed circuit boards are rigid and flexible too. Along with this, rigid-flex circuits can be collapsed or persistently flexed while keeping up the states of the zones that need additional help. However, Rigid-flex PCBs are generally multi-layered and contain flexible circuit substrates that get together with the rigid sheet.

Additionally, in terms of PCB design, we are tasked with fitting a square peg into a round hole. However, fitting thousands of diverse components onto a board is no longer than a dollar bill. We always seem to be limited to the 2D plane of predetermined space within our device or equipment. But, now we easily make several 3D devices with the use of this advanced PCBs technology.

Furthermore, there is no doubt that PCBs have been used from several previous years, but at that time, the size of the PCB was so large, and that’s why we have large equipment, just like computers. But nowadays, we reduced the size of the PCBs to make the devices much smaller and sexy. Nowadays, you can see that we have many more digital devices like smartphones, TV, microwaves, and speakers in smaller sizes which are easier to use and carry.

Here in this blog, we will discuss the ample benefits of rigid-flex PCB.

The rigid-flex technology has enhanced the digital world in a very effective way. Let’s explore what other benefits you will get with rigid-flex printed circuit boards.

Accessible To Form In Any Device!

You may see that a rigid-flex printed circuit board has its own section, and that’s why we are no more bound by the space within the device. We can now form our PCB around the device in 3D space, and it means no mounting surface is off-limits to where we can put our printed circuit boards. Even as long as we can run a flex material from one rigid printed circuit board to the next, we can integrate the design into any shape and design. In short, with rigid-flex technology, we can make every smaller device that we want.

Lightweight And Compact!

As discussed above, the rigid-flex PCB is of smaller size, so it is clear that the weight of the circuit board is significantly less. And of course, it is compact too. At the time of designing rigid-flex circuits, only flexible material was used; that’s why we need only smaller space to make any device.

No Need Of Solder Joints To Design Rigid-flex PCB!

A rigid-flex printed circuit board is constructed by sandwiching a flex board in between two or more rigid boards. And this method of assembly is wonderful due to not using extra solder joints, connections, or contact crimps. Even it will only assist in increasing its overall structural integrity as it’s put through its flexible paces.

Less Material = Less Cost!

At the time of constructing rigid-flex circuit boards, we need to use fewer materials. And it is the reason behind rigid-flex circuits that cost less. So, now making more devices has become less expensive.

Final Word!

As we talked about above, rigid-flex PCBs increase the chances of making more 3D devices. And, yes, these PCBs are smaller in size and need less space to fit in any device and make it successful. However, if you have any PCB projects or want to know more about PCB construction, just reach out to us at Dynamic Flexible & Rigid Printed Circuit Design.