Knowing About The Types of (PCB) Printed Circuits Boards

A BASIC INTRODUCTION

PCBs are primarily made up of thin strips of conducting material. It mechanically assists and electrically connects different components making them more reliable and give them the ability to bear more load.

PCBs are flexible circuit boards that are molded and shaped to reduce the size, weight, and structure of the equipment as per the requirement, maintaining its sustainability and effectiveness. We encounter dozens of accessories in everyday life which are assembled using complex electrical circuits.

Before moving into the types of printed circuit board designs, let us discuss some of their benefits.

Resistance to high temperature:

Printed circuits board works ideally under high-density and high-temperature load applications. They offer high-quality electrical transmission effectively and efficiently. The diversity of PCBs enables it to be a significant part of accessories measuring humidity, moisture, and pressure, etc. These are highly durable and can easily withstand extreme temperatures and can be used in robust environments. Because of the polymer substrate and streamline design of the printed circuit board, flex PCB’s provide better airflow and heat dissipation.

ENHANCED electrical connectivity.

Flex PCB’s provides improved electrical performance because their low dielectric constant allows the electrical signal to convey rapidly and lessens the noise factor. Higher heat transfer properties make the assembly work easier and faster. Printed circuit boards for communication have also aced the market and have significantly enhanced the overall quality in the field of telecommunication.

Getting started with types!

PCBs are constructed using state-of-the-art technology, which enables this product to have vast applications. These are classified into various types, which are discussed below:

TYPE NUMBER 1: SINGLE-SIDED PCB’s

Having just a single layer of the substrate or the base material, single-sided printed circuit boards only contain one layer of the substrate or the base material.

One side of the board is typically covered with a conductive material, primarily copper, as it is an excellent conductor.

A productive layer of solder sits on the top of the segment, which is then covered with a silkscreen coat.

It is applied to the top – marking the parts on the board. A single-sided printed circuit board primarily used for simple electronic designs. They are cheap but are used infrequently due to their inherent design limitations.

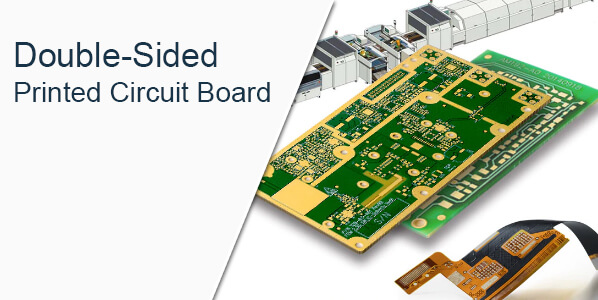

Type number 2:- Double-Sided Printed Circuit Board

Double-Sided PCBs, commonly referred to as two-layer printed circuit boards, are coated with conductive layers on both sides of the substrate, and other parts are linked to both sides as well. Holes allow circuits on one side to connect to circuitry on the other. Multi-layer circuit boards connect the circuits on each side using one of the two methods:

- Methods number 1:- THROUGH HOILE TECHNOLOGY

It involves inserting tiny wires through the holes, knows as lead, which enables the soldering of different components on both sides. These are much reliable and offer more diversity when compared to single-layer printed circuit boards

- Method number 2:- SURFACE mount TECHNOLOGY

This technology uses small leads instead of wires, which connects to both sides of the board, enabling the components to get connected with each other. You can perform more operations effectively because more circuits can be integrated into a much smaller space. Double-sided printed circuit boards that are based on this technology are lighter in weight and offer much faster electrical connectivity.

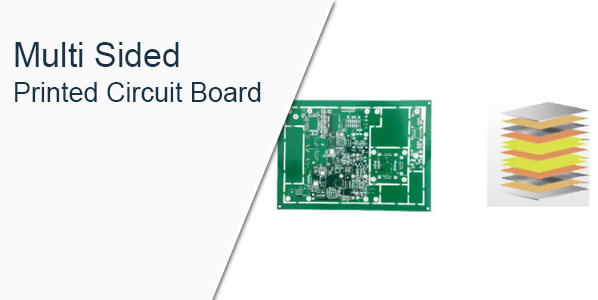

Type number 3:- Multisided printed circuit board

A multi-sided design saves much more space, still offering an adequate flow of current flow. These have multiple boards that are integrated together and can connect to each other through holes in the board. They have several layers of substrate board that are separated by an insulating material to avoid any short circuits. These can have multiple boards, depending upon the demand and the type of use.

Type number 4:- automotive printed circuit board:

Electronic circuits have been playing an essential role in advancing the technology of automotive industries. A modern car comprises more than 200 hundreds of electrical components, such as sensors and electrical processors that are primarily composed of electrical circuits.

To have a proper working of such dynamic systems, companies use multi-layered printed circuit boards to make such systems reliable and effective. Printed circuit boards have aced the automotive market, enhancing the workability and efficiency of the vehicles and taking them to a whole new level of technology.

Automotive electronic systems have to face different environmental conditions such as rain, humidity, vibration, and magnetic interferences, and electrical surges.

Therefore, automotive circuit boards are uniquely designed to withstand such extreme conditions and work effectively. Dynamic FPC Designs, being one of the most preeminent manufacturers of PCBs, provide their customers with the finest quality of the circuit. That offers high durability in such robust conditions.

Type number 5:- PCBS FOR 3D PRINTER:-

Printed circuit board designs for 3D printers are designed to handle more complex functionality.

These are manufactured using high-quality materials, thereby increasing the overall cost.

They are more powerful and have a much enhanced operating speed and power.